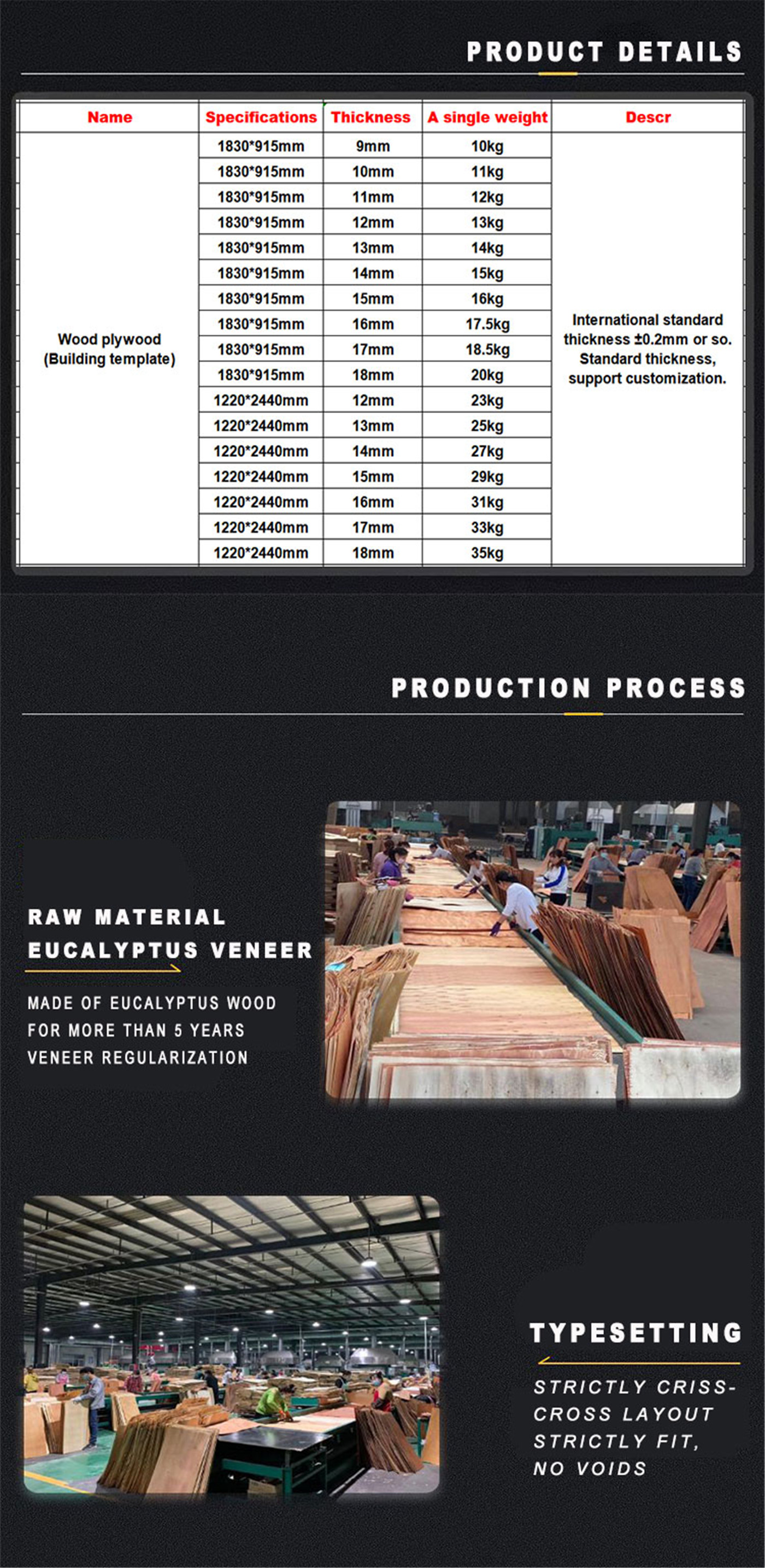

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Brand Name | Xinhang | Core | pine, eucalyptus or requested by clients |

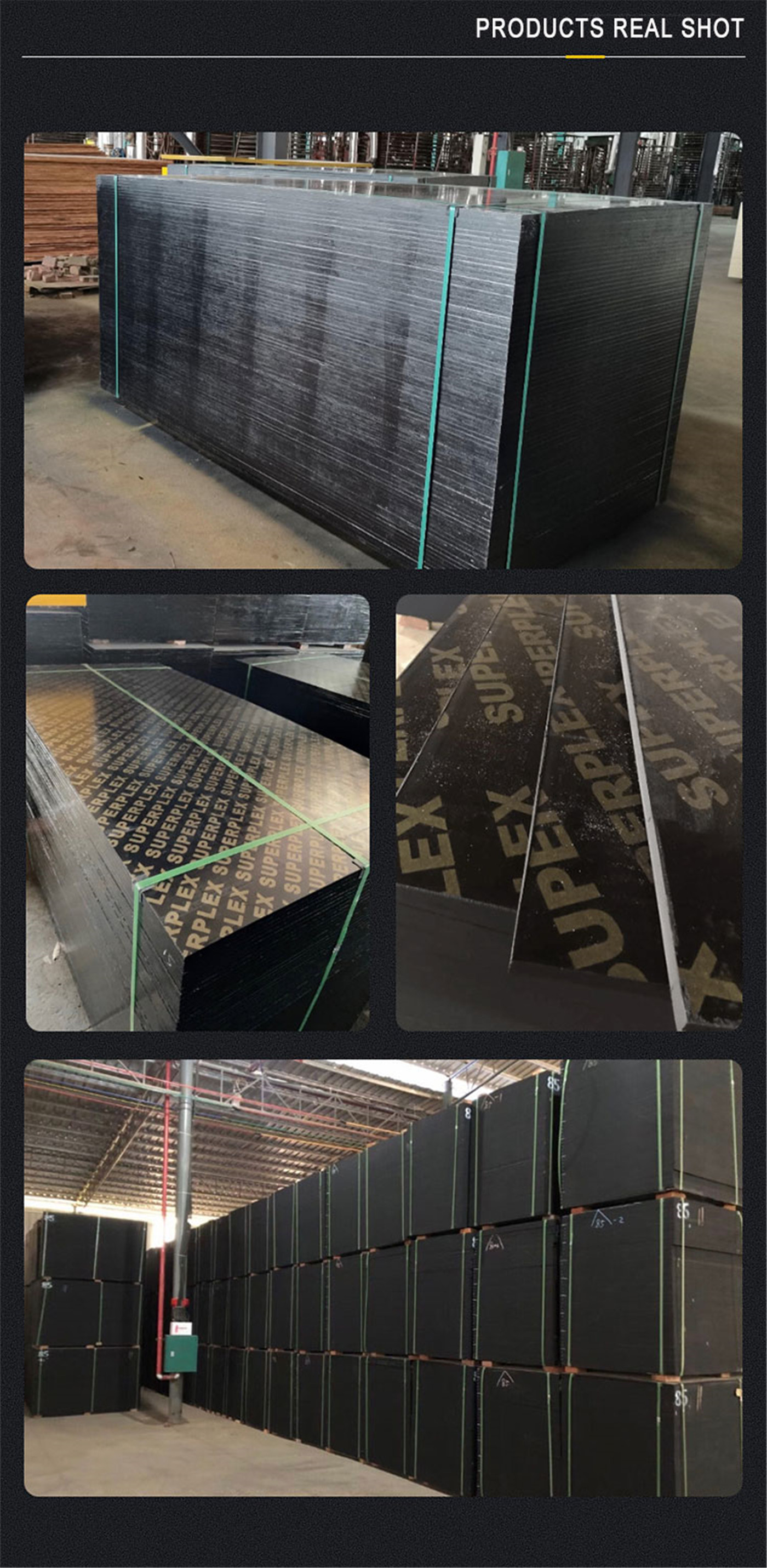

| Model Number | HIGH QUALITY BLACK FILM FACED PLYWOOD FOR CONSTRUCTION | Face/Back | black(can print log) |

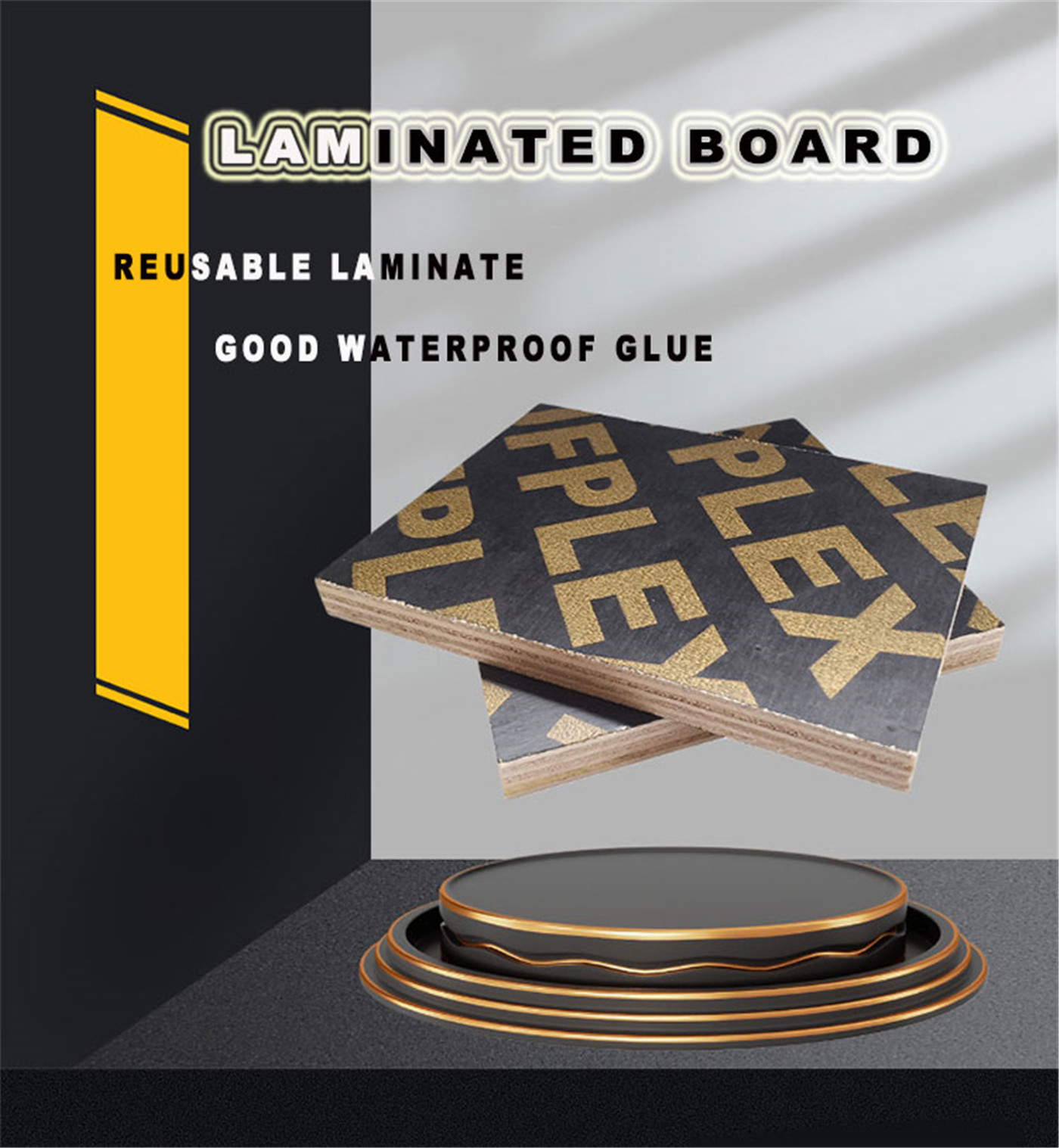

| Grade/Certificate | Glue | MR, melamine, WBP, phenolic | |

| Size | 1830*915mm/1220*2440mm | Moisture content | 5%-14% |

| Thickness | 11.5mm~21mm or as required | Density | 600-690 kg/cbm |

| Number of Plies | 8-11 layers | Packing | Standard export packing |

| Thickness Tolerance | +/-0.3mm | MOQ | 1*20GP. Less is acceptable |

| Usage | Outdoor, construction, bridge, etc. | Payment Terms | T/T, L/C |

| Delivery Time | Within 20 days after order confirmed |